greybeard

Herd Master

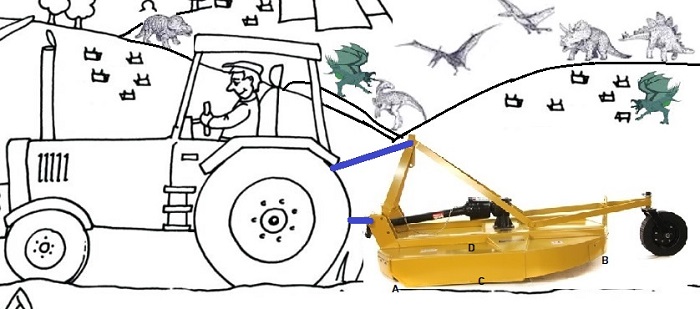

One of the mistakes I often see people do with 3pt pto driven rotary mowers is not having them adjusted right regarding height..both height off the ground and height looking front of mower to the rear of the mower. For light easy cutting, it's usually not an issue, but in thick high forage it can make a big difference.

Normally, the front and rear of the mower (A TO B) should be level with each other, with 1/2 the weight of the mower on the lift arms and 1/2 the weight of the mower on the trailing wheel(s). But, in thick stuff, I find I can do better if the front is a little higher than the rear. This takes some cutting stress off the blades as they come around to the front of the mower, and then as the tractor moves forward and the blades make there cut across the rear of the mower, final cut height is made. You can adjust how low the trailing wheel drops and how much weight it bears by moving pins or bolts on the tail wheel bracket and by lengthening or shortening the center link.

Never, should the mower's skid plates (C) be constantly dragging the ground like you see in the drawing below..

You want to be carefull about stalling the pto shaft and applying power to a stalled mower........you will be popping shear pins soon, or worse:

(Yes, that's mine..hub on the ujoint that connects to a gearbox was rusted to the gearbox input shaft and the hub could not slip enough to shear the pin....it twisted and broke the driveline instead. It's from a 3Pt post hole auger, but I have seen the same thing happen on mowers)

90% of the time, stalling a mower is caused by excessive forward speed and a low PTO rpm combination.

Tractors today are rated and advertised by how much engine HP they have, but there is also a drawbar HP rating and a PTO HP rating. Of the 3, PTO HP is always the lesser.

Normally, the front and rear of the mower (A TO B) should be level with each other, with 1/2 the weight of the mower on the lift arms and 1/2 the weight of the mower on the trailing wheel(s). But, in thick stuff, I find I can do better if the front is a little higher than the rear. This takes some cutting stress off the blades as they come around to the front of the mower, and then as the tractor moves forward and the blades make there cut across the rear of the mower, final cut height is made. You can adjust how low the trailing wheel drops and how much weight it bears by moving pins or bolts on the tail wheel bracket and by lengthening or shortening the center link.

Never, should the mower's skid plates (C) be constantly dragging the ground like you see in the drawing below..

You want to be carefull about stalling the pto shaft and applying power to a stalled mower........you will be popping shear pins soon, or worse:

(Yes, that's mine..hub on the ujoint that connects to a gearbox was rusted to the gearbox input shaft and the hub could not slip enough to shear the pin....it twisted and broke the driveline instead. It's from a 3Pt post hole auger, but I have seen the same thing happen on mowers)

90% of the time, stalling a mower is caused by excessive forward speed and a low PTO rpm combination.

Tractors today are rated and advertised by how much engine HP they have, but there is also a drawbar HP rating and a PTO HP rating. Of the 3, PTO HP is always the lesser.

Last edited: