redtailgal

New Member

- Joined

- Dec 8, 2010

- Messages

- 5,369

- Reaction score

- 27

- Points

- 0

yes YES yes YES yes! my sentiments exactly!WildRoseBeef said:And of course a good man gate can't be one where you have to screw around with a bloody chain. Ever since I've helped the vet with working with cattle in a handling facility I've loved the latches where they simply lock when you push them shut. That's what a good man-gate should have, not some stupid chains.

They have since reworked the gates, they can now be closed without even entering the chutes. They swing back to the panels and latch, so we can undo the latch and give them a push and WALA!

My friend has also added a rotating press, so I am excited about working with that this summer. She does have to battle hoof rot frequently, so this should make caring for those hooves so much easier. Easier access to feet is a big deal for me, cattle hooves are not my favorite area.

So if/when I have to or want to take out those posts, I gotta call the natural gas company to stake out the area before I start a-diggin'!! And it's those posts that are getting really loose, since I was climbing up on the chute and seeing how loose the posts are by reefing on them a bit. The next loading chute will NOT be one that has posts sunk in, preferably a sturdy yet portable chute would be ideal, since it could be moved in if/when a cattle-liner is needed to haul out the backgrounder calves and moved for a livestock trailer to back up to to haul out any culls or anything that doesn't need a big 50' long cattle liner.

So if/when I have to or want to take out those posts, I gotta call the natural gas company to stake out the area before I start a-diggin'!! And it's those posts that are getting really loose, since I was climbing up on the chute and seeing how loose the posts are by reefing on them a bit. The next loading chute will NOT be one that has posts sunk in, preferably a sturdy yet portable chute would be ideal, since it could be moved in if/when a cattle-liner is needed to haul out the backgrounder calves and moved for a livestock trailer to back up to to haul out any culls or anything that doesn't need a big 50' long cattle liner.  The system we have right now is in that no-no position.

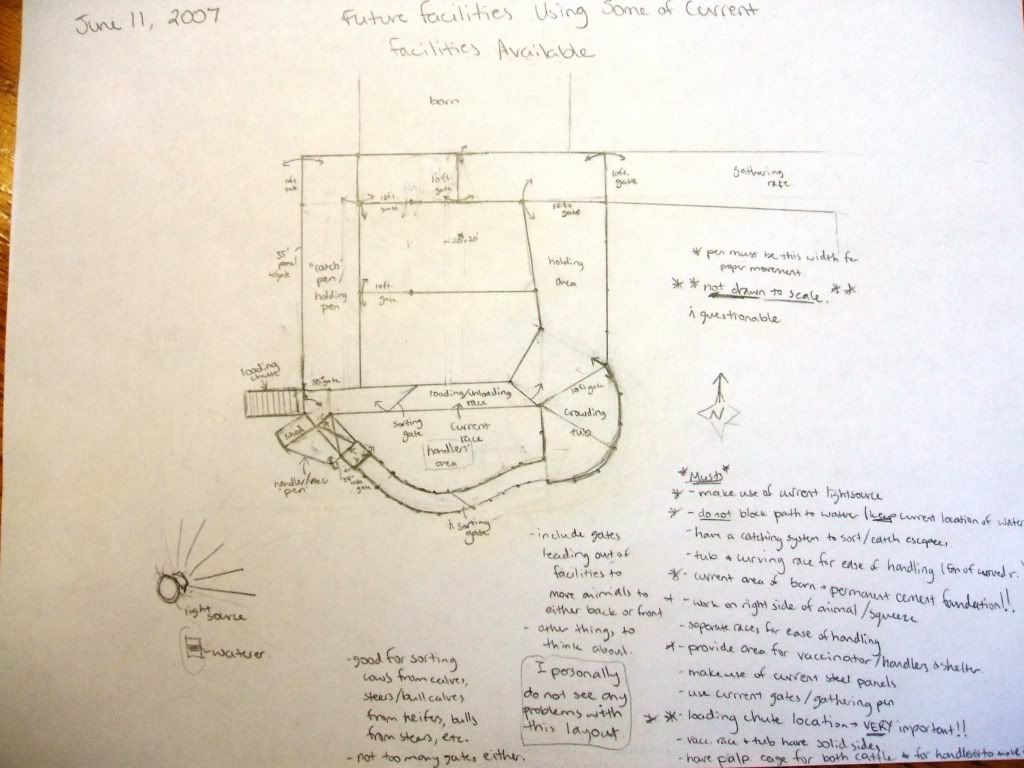

The system we have right now is in that no-no position.  Which means that I could have the system stay where it is for now, but I really need to work on a plan that has these facilities in a north-south direction in such a location that I still have access to electricity and power, and trucks and trailers are still able to get at without having too much driving around and backing-up to do. With the location of the barn, the waterer, the low spots and high spots, the quanset, the pump-house, trees, etc. etc. etc. I've got a bit of a challenge on my hands!!

Which means that I could have the system stay where it is for now, but I really need to work on a plan that has these facilities in a north-south direction in such a location that I still have access to electricity and power, and trucks and trailers are still able to get at without having too much driving around and backing-up to do. With the location of the barn, the waterer, the low spots and high spots, the quanset, the pump-house, trees, etc. etc. etc. I've got a bit of a challenge on my hands!!

We got about 12 inches of the white stuff fall over the weekend, making it fun shoveling. At least we have a good little snow blower, and the neighbor was kind enough to come up with his big loader to dig out our drive way for us: we had a 3' high drift near the end there.

We got about 12 inches of the white stuff fall over the weekend, making it fun shoveling. At least we have a good little snow blower, and the neighbor was kind enough to come up with his big loader to dig out our drive way for us: we had a 3' high drift near the end there.